Introduction

Brass stamps have long been the preferred choice for leather workers and other artisans due to their durability and precision. With the advent of CNC milling technology, creating intricate designs and 3D objects has become more accessible than ever before. However, maintaining a balance between high-quality craftsmanship and affordable pricing remains a constant challenge. In this blog, we'll dive into the process of machining brass stamps with a CNC mill and explore the struggles of producing 3D objects at a reasonable cost.

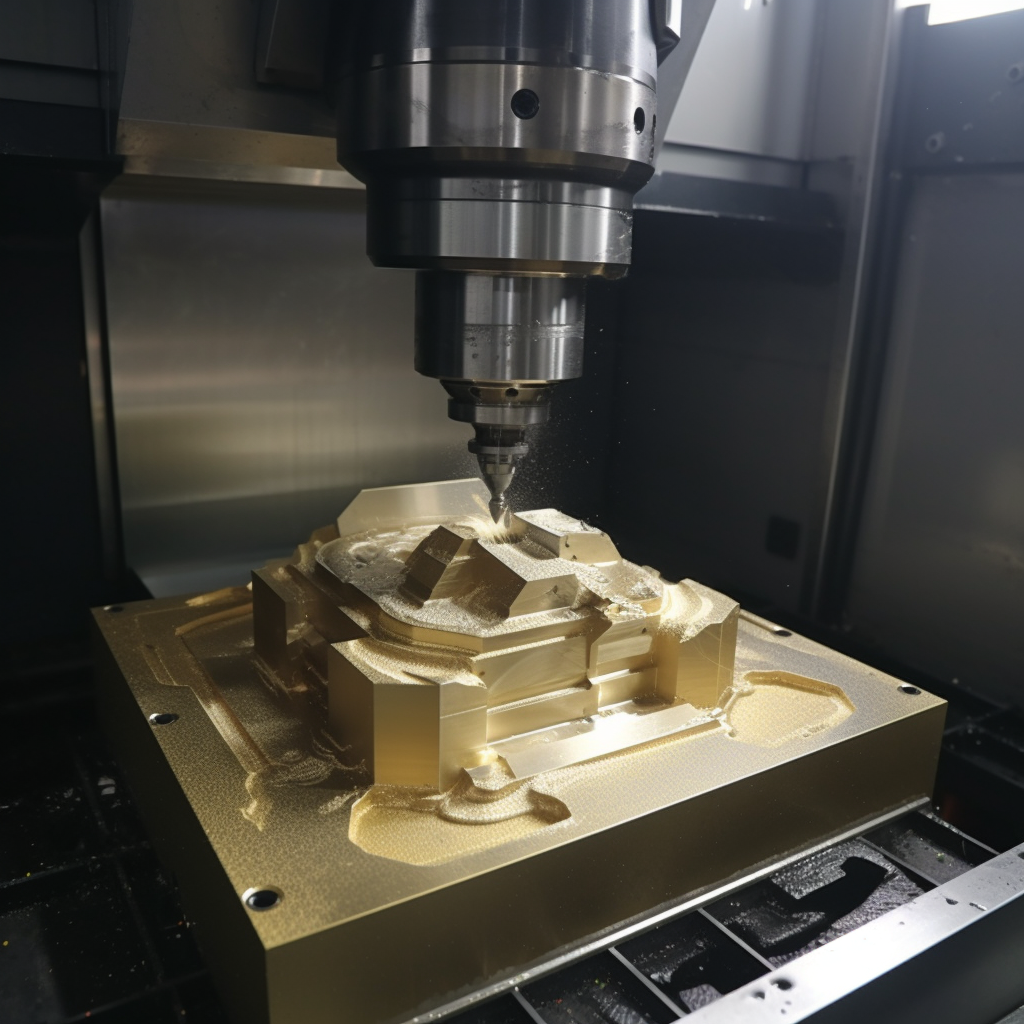

The CNC Milling Process for Brass Stamps

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that employs computerized controls and rotating cutting tools to gradually remove material from a workpiece. The process starts with a digital 3D design, which is then converted into a series of machine-readable instructions. The CNC mill follows these instructions to create the final product with impeccable precision and accuracy.

When it comes to brass stamps, the milling process is particularly intricate. The CNC machine must carve out the desired design while maintaining the structural integrity of the stamp. The process often involves multiple passes, each removing a thin layer of material until the final design emerges.

Challenges of Creating 3D Objects with CNC Milling

Despite the precision and accuracy offered by CNC milling, creating complex 3D objects remains a challenge. Some of the key difficulties include:

-

Tool accessibility: As the complexity of the design increases, reaching certain areas of the workpiece can be difficult. This may require the use of specialized cutting tools or multiple setups, which can increase production time and cost.

-

Material waste: Due to the subtractive nature of CNC milling, a considerable amount of material may be wasted during the process. This not only increases the overall cost of production but also has environmental implications.

-

Time constraints: Crafting intricate 3D designs can be a time-consuming process, as the CNC machine must make numerous passes to achieve the desired level of detail. This results in longer production times, which can affect pricing.

Balancing Quality and Affordability

To create high-quality brass stamps at a reasonable price, we continually strive to optimize our production process. Some strategies we employ include:

-

Efficient toolpaths: By optimizing toolpaths, we can minimize production time and reduce material waste. This not only helps lower costs but also improves the quality of the final product.

-

Advanced software: Using advanced CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software enables us to create highly accurate designs and streamline the CNC milling process, ultimately reducing production costs.

-

Bulk production: By producing brass stamps in larger quantities, we can take advantage of economies of scale and reduce the cost per unit.

Conclusion

Machining brass stamps with a CNC mill has revolutionized the way artisans create intricate designs and 3D objects. Despite the challenges involved in crafting complex 3D objects while keeping prices affordable, we continue to refine our production techniques and leverage technology to deliver high-quality brass stamps at a reasonable cost. Our commitment to craftsmanship and affordability ensures that our customers receive the best tools for their leather working and other artistic endeavors.